In the ever-evolving landscape of cosmetic packaging, the role of plastic instrument molded enclosures cannot be overstated. Xinluyao, a leading manufacturer based in China, specializes in crafting high-quality enclosures using a variety of materials such as PS (Polystyrene), PP (Polypropylene), PA (Nylon), POM (Polyoxymethylene), ABS (Acrylonitrile Butadiene Styrene), PC (Polycarbonate), and PC+ABS blends. These materials, chosen for their unique properties, ensure that the enclosures not only protect the contents but also meet the stringent requirements of the cosmetics industry. Let's explore how Xinluyao leverages these materials and their properties to deliver superior cosmetic packaging solutions.

Xinluyao's expertise lies in understanding the nuances of each material and selecting the most appropriate one for the task at hand. For instance, PS is favored for its clarity and stiffness, making it suitable for transparent containers that allow consumers to see the product inside. PP, known for its toughness and chemical resistance, is ideal for bottles and jars that may come into contact with aggressive cosmetic formulations. PA offers high strength and dimensional stability, while POM provides excellent wear resistance, making it perfect for components that endure repeated use.

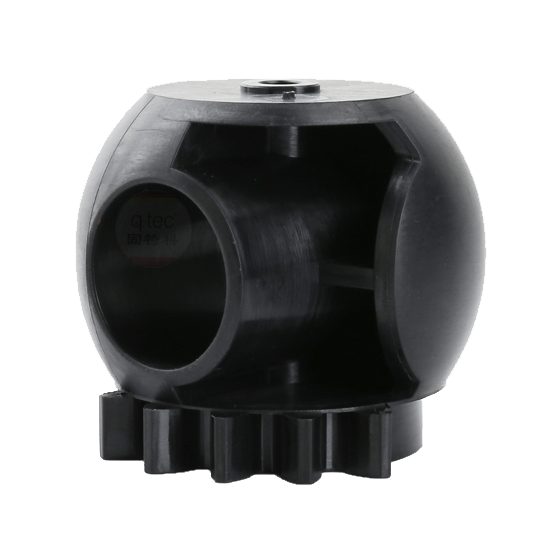

ABS, with its combination of rigidity, toughness, and ease of molding, is widely used in the cosmetics industry for its aesthetic appeal and durability. PC, characterized by its high impact strength and transparency, is often used for high-end cosmetic packaging. The PC+ABS blend combines the best of both worlds, offering superior impact resistance and mechanical properties, making it a versatile choice for a wide range of applications.

In addition to plastics, Xinluyao incorporates silicone elements into their enclosures, taking advantage of silicone's sealing, waterproof, dustproof, and wear-resistant properties. Silicone seals and gaskets are crucial for ensuring that the enclosures remain airtight and protected from environmental contaminants. This is particularly important for cosmetics, where product integrity and shelf life are paramount.

Xinluyao goes beyond mere material selection; they offer custom manufacturing services tailored to the specific needs of the cosmetics sector. Whether it's a unique shape, specialized finish, or custom color, Xinluyao's team of engineers and designers collaborates closely with clients to bring their visions to life. This level of customization ensures that each enclosure not only meets functional requirements but also aligns with the brand's aesthetic and marketing goals.

As a leading manufacturer in China, Xinluyao operates from a state-of-the-art facility equipped with the latest injection molding technologies. The company's commitment to quality is evident in every enclosure produced, from the precision of the molds to the meticulous inspection processes. Xinluyao's dedication to innovation and customer satisfaction has earned them a reputation as a trusted partner for businesses around the world.

Xinluyao offers competitive wholesale pricing and flexible order quantities, making it an attractive choice for suppliers and distributors looking to source high-quality cosmetic enclosures. The company's extensive global network ensures timely delivery to clients worldwide, while their commitment to customer service guarantees a seamless purchasing experience.

Xinluyao stands out as a beacon of innovation and quality in the world of plastic instrument molded enclosures for the cosmetics industry. By leveraging the properties of materials like PS, PP, PA, POM, ABS, PC, and PC+ABS, along with the versatility of silicone, Xinluyao creates enclosures that are not only functional but also aesthetically pleasing. Whether you're a cosmetics brand looking for custom packaging solutions or a distributor seeking a reliable supplier, Xinluyao is your go-to partner for excellence in cosmetic packaging.